Diesel additives have become more of a requirement for users as new regulations are affecting the make-up of the diesel. Diesel may look the same but its processing has changed and the technical makeup has been changed to make it more environmentally friendly. It is these changes that mean there is a requirement for a diesel additive as without it user’s tanks, injectors, pumps and filters are more vulnerable to costly severe problems associated with modern diesel.

Changes in Diesel Composition

In the mid-1990s it was decided that the levels of sulphur should be reduced in diesel. The sulphur is added to act as a lubricant for the operation of the fuel pumps and valves. This sulphur also helps with bacterial and fungal contamination. The drop in levels of this sulphur was dramatic from nearly 2000 ppm to now been less than 10 ppm. This has a significant effect on the ability to do the roles it was designed for.

Another change that has been made to modern diesel has been the introduction of biofuel, FAME. This has become a requirement for environmental terms across the globe, and it is this FAME that provides food for bacteria to grow.

Degradation of Diesel – Why Diesel Additive is required

The changes in the diesel composition mentioned above mean that today’s Diesel no matter where it comes from begins to degrade from the moment it leaves the refinery. All brands of diesel go through this degradation as it is a natural occurrence which occurs in 2 ways:

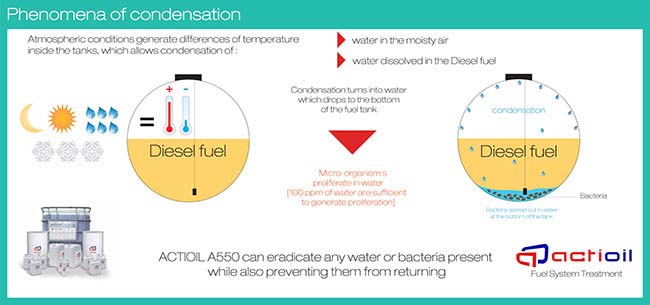

Condensation – this takes place inside the tank. Diesel contains water and when humid air reaches the inside of the tank depending on the temperature of this air cold or hot the water will freeze or evaporate, evaporation also occurs in a tank attached to an engine when the unused hot fuel returns to the tank on power down. These occurrences cause water droplets on the inside of the tanks and this water can cause tanks to erode thus dropping water and dirt into the diesel. This causes a chain of reactions which degrades the fuel and forms the Sludge.

- Micro-organisms develop – Bacteria, Fungi & Yeasts.

- Oxidation of the fuel occurs due to water and air being present.

- Corrosion & erosion of the tanks.

The reduction of sulphur and the addition of Biofuel – as mentioned above there is less lubricity in the diesel and there is increased conditions for the growth of micro-organisms which form the sludge and sediments which result causing problems throughout the diesel system from the storage tank to the engine.

This degradation of the diesel harms the fuel and in turn harms the storage tanks and engines that is used in. Users will see the loss of power, blocked filters, damaged injectors and many more problems associated with the diesel system. This degradation also allows for the presence of more water which during cold weather makes the diesel more susceptible to gelling (Freezing)

Diesel Additive – the solution to diesel degradation.

The only way to combat the problems associated with this modern diesel is to use additives or treatments and to keep using them. While there are a lot of diesel additive and treatment products on the market there are some big differences in them. Most additives have to be added every time you fill the tank either the storage or the machine/vehicle tank. Others don’t have any lubricity added to them which doesn’t help with the lack of lubricity in the modern diesel and many don’t combat all the problems that cause bacteria to grow. However, there are some products which work very well and have been well tested and used.

Actioil Diesel System treatment is one of these such diesel additives. Actioil only has to be used once a year in the vehicle/machine tank or once every 3 years in a storage tank and once used it solves any problems currently there and also prevents problems occurring again for the duration of time it lasts. Actioil treats up to 22 problems at once the more than any other product available. Some of these problems include:

- Eliminates & prevents the reappearance of bacteria.

- Improves the lubricity of the fuel which has been lost due to the removal of sulphur.

- Forms a protective nano-film that prevents corrosion of the tanks & diesel systems.

- Atomises water particles & encompass them so they are eliminated together with the fuel.

- Protects the pumps & injectors.

- Restores the performance of diesel.

- Increases the effective life of the fuel from 30 days to 9 months.

- Prevents the formation of paraffin & the crystallisation of the fuel.

- Transforms the sludge in the base of your tank back into fuel.

- Decreases the freezing point of the fuel

Actioil is used worldwide and is approved by some of the largest fuel suppliers and engine manufacturers some of which you can see below.