With spring just around the corner, it can be a very busy time on a farm, day to day activities are continuing, and preparation for new growth is important to get right to ensure an efficient year. Part of this preparation on many farms is maintenance checks on the farm machinery to ensure it is ready for another busy season. Regular maintenance checks on all farm machinery are critical to ensure efficient running and prevent unscheduled downtime which can be very costly if your machinery breaks down when you need it most.

Part of any farm machinery maintenance check should be a rigorous check on the lubricant and coolants to ensure levels are correct and there is no sign of leakage. It is also important to remember when checking these levels to consider when was the last time these fluids were changed as opposed to just topped up. Most years, some operators consider just topping up fluids as opposed to a full change and in some cases, where usage is low or where good quality lubricants are being used this might have looked to suffice. To some, this is seen as a way of reducing maintenance costs, however, these perceived savings are false, as continued topping up without a full change at the recommended intervals (500 hrs for engine & 2,000 hrs for backend/transmission) can lead to more costly issues long-term (Always follow OEM recommendations). As;

- Once a lubricant has been run through an engine/backend and returns to the sump, it will have cleaned all the parts it ran through and collected particles of dirt, metal from wear & tear and many other particles that can become dislodged internally. Lubricants are designed to continue to perform even with particles in them and indeed high-quality lubricants will perform longer. Still, all lubricants will get to a point where the amount of particles/contaminates will decrease the effectiveness of the lubricant which will lead to increased wear and tear. (Consider a chip pan, topping up does not remove the dirt from the oil and the oil gets very dark with dirt the longer it’s left, only a full drain will remove the dirt.)

- For operators using any equipment that requires connection to your tractor’s backend, regularly changing is even more important as your backend oil flows from the tractor to the equipment and back again resulting in the oil mixing with any oil left in the equipment from the last time it was used which carries several risks.

- The equipment may not have been used in a long time and so the oil in it could be old and may have lost its properties.

- Dirt on the connections getting into the system when linking up.

- Where you have mixed fleet using the same equipment or sharing equipment with others, there is a risk of mixing with oil from another machines that used the equipment before you, which may have contaminations of its own or a different lower spec oil due to some manufacturers having different requirements or other operators using inferior cheap lubricants.

- Grease, like the oils will collect any dirt caused by wear & tear but in a lot of cases where grease points are not sealed the grease also catches dust and dirt externally to prevent it getting into the points it is protecting. By continuing to top up the grease instead of changing regularly, this dirt has been kept in the system and when it builds up the grease will no longer prevent it from getting to the machine parts and causing damage.

- Coolant/Antifreeze does so much more than just preventing your engine from freezing during colder weather, it cools your engine down by removing the heat caused during operation to protect the engine from overheating and ensure its efficient operation. Topping up with water alone will reduce the properties of the coolant in your system and reduce its effectiveness.

Another easy temptation for operators to save on the upfront maintenance costs is to look towards the cheaper brands of lubricants, especially recently as according to Eurostat, cost of lubricants have risen by 59% since 2021. This however results in a short-term gain and a long-term loss, as most will fail and cause breakdown at the most important time. These cheaper, lesser-quality lubricants do not go through the rigorous tests a fully approved lubricants from trusted international brands has to and are usually blended to the minimum requirements of the manufacturer’s specification, using the least amount of additives to meet the lower end of the tolerance levels of specifications to cut costs, thus not being as reliable to ensure your machine is performing at its potential.

The importance of machine longevity and performance to Irish farmers is at the heart of the reason why Finol Oils have been a trusted lubricants partner to the Irish farming community for over 40 years. Finol has been providing farmers with a wide range of high-quality approved products from trusted international brands such as TotalEnergies, Elf & Petro-Canada and our own Finol brand, all of which are designed to meet the needs and ensure maximum efficiency of machinery on the farm. Finol has identified the most important parts of most tractors to check the fluids in regularly

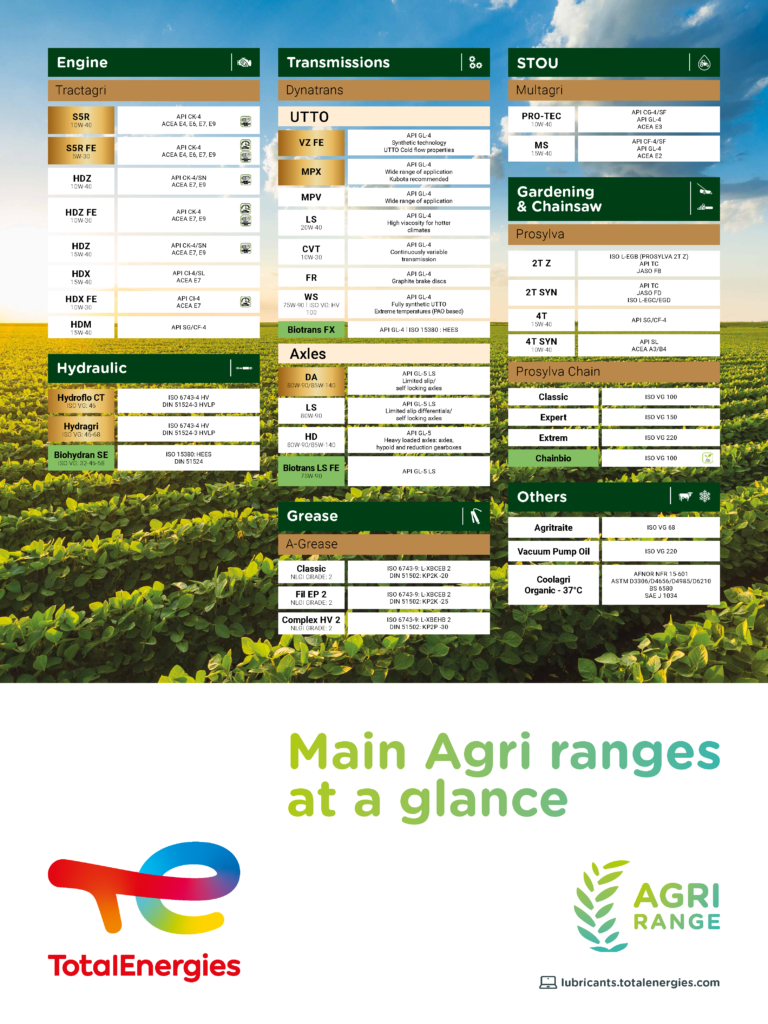

- Engine – Choosing the right engine oil is very important, most modern engines are switching away from the common long drain 15W-40 and depending on the engine the requirement could be Low Ash 15W-40, 10W-40 or 5W-30, so it is important to ensure you check the manufactures requirements for your machine and use approved high quality engine oils such as TotalEnergies Rubia range, Petro Canada’s Duron range or Finol’s Performance range.

- Backend/Transmission/Hydraulic – Whilst most machinery use the same backend oil most referred to as 10W-30 or 80W wet brake oil there are some manufactures with different requirements such as 10W-40 or a dedicated CVT transmissions so be sure to use the correct high quality backend oil such as TotalEnergies Dynatrans range, Petro Canada’s Duratran range or Finol’s AgriworX range and always be sure to replace the oil at regular intervals especially if sharing hydraulic equipment with other tractors.

- Differential/Hubs – Keeping the hubs cool under severe temperatures during operation is very important and high-quality oils will ensure this. Its especially important to remember the front hubs when the there is a front loader on the tractor as oils may need to be replaced more often due to even more use as a result.

- Coolant – Using the correct coolant/Antifreeze and making sure not to mix coolant types is important to avoid gelling in the system. TotalEnergies Coolelf range or Finol’s Coolant range offers all the different types of coolants most farm machinery need.

- Grease Points – Greasing is the most common part of maintenance checks that’s forgotten but it is highly important to grease regularly and to change the grease regularly to avoid wear & tear. Another important point to remember is to not over grease, i.e., pumping grease till it pops out the side or the grease gun cant pump anymore. This can damage the components just as much as not having any grease at all.

- Other fluids required – Screenwash, AdBlue, Hydraulic Brake Systems, Transfer Box.

As well as providing the products needed for all these important parts, we also provide a comprehensive range of services which includes technical advice for those who want to gain a better understanding of how to use their lubricants for maximum efficiency. This ensures that you can be sure in your purchases from us, while also optimising productivity levels through better knowledge about using the best fluids in your equipment to ensure minimum downtime and learning how some lubricants can help reduce fuel usage. To learn more about our range and how it can benefit your productivity, please contact us at 3531223852 or agri@finol.ie