As the country now emerges from the Covid-19 pandemic, the agricultural industry and others are facing even more challenges as input costs have risen over the past 12 months.

Rising prices for fuel, fertilizer, parts, feed, building materials; and labour, to name a few, are already impacting spring activities in the agricultural industry and are forecasted to bring down farm incomes in 2022.

Whilst the impacts of these costs are out of the control of the farmer, some measures can be taken to reduce the impact of these rising costs.

Modern farm machinery fleets are a major component of any farm’s running costs and are vital for farming activities. This machinery can be exposed to some of the most extreme conditions, most demanding usage and the harshest ground conditions.

Therefore, it is vital that the care and maintenance of this equipment is a high priority for any farm to ensure the reliability and efficiency of the machinery so that it performs to its full potential and avoids unnecessary downtime.

By taking a few steps, you can reduce the running costs, maintenance costs and fuel usage of your machinery fleet.

Machine Maintenance

One of the simplest ways to contribute to optimal machinery performance is to introduce a daily preventative maintenance check into your daily activities.

This daily check is as simple as:

- Cleaning the machinery;

- Visually inspecting all major components and joints to look for any abnormalities, i.e. wear on moving parts outside of normal wear and tear;

- Checking tyre pressure to see if it is correct for the planned activity and ground type;

- Checking fluids and greases to ensure there are no leaks, and all are at the right levels.

These simple checks can help ensure the longevity and performance of your machinery.

However, to make a substantial impact on the maintenance and fuel usage of the equipment, most manufacturers recommend that you use high-quality genuine or approved parts in your machinery. Lubricants and fluids are some of the most vital parts of any engine or machinery.

Like genuine parts, high-quality approved lubricants or lubricants meeting the machinery requirements are designed and manufactured to perform to the machinery manufacturer’s approval performances. Approved products are rigorously tested to ensure they exceed these performance levels.

These lubricants are formulated to ensure they help the machinery perform to its full potential. Whereas cheaper, lesser-quality lubricants do not go through these rigorous tests and are usually blended to the minimum requirements, using the least amount of additives to meet the lower end of the tolerance levels to cut costs, thus not being as reliable to ensure your machine is performing at its potential.

Higher-quality lubricants designed to exceed the machinery performance levels can be more expensive upfront, but have numerous benefits over the cheaper options, including:

- Machine longevity, to ensure your machine components last longer, reducing breakdowns and extending the life of the machine;

- Longer drain intervals, synthetic lubricants have a longer lifespan which, depending on the machine and usage, allows for the drain intervals to be extended, reducing the amount of oil and the labour required for oil changes;

- Machinery performance, high-quality lubricants prevent the formation of deposits in the engine allowing it to run more efficiently, thus increasing reliability, boosting its performance and enhancing productivity;

- Fuel economy, lowering the lubricants viscosity and enhanced lubricity at lower temperatures allows for lower overall friction and easier start-up, delivering less resistance and reducing the fuel usage of the engine.

These higher-quality lubricants can significantly lower your overall costs and save you money in the long term. These products cut your maintenance costs through reduced oil usage; lower maintenance labour hours; fewer parts replacement; less waste-oil disposal; and minimised costs of lost production due to machinery downtime.

TotalEnergies fuel economy lubricants for agriculture

TotalEnergies are among the very few oil companies that can offer a dedicated range of lubricants for use in agriculture machinery that not only improve the performance of equipment, but reduce the environmental impact and running cost of the machine by reducing the fuel usage, whilst achieving optimum performance levels of the engine.

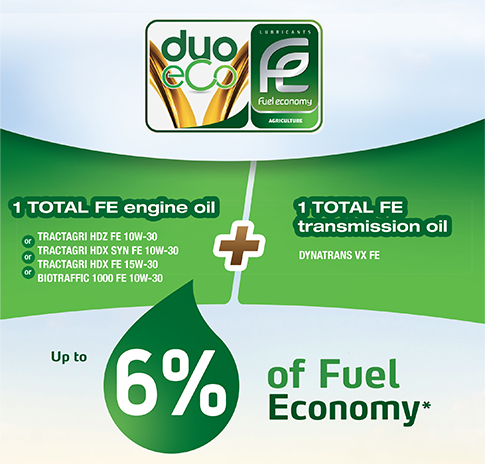

The main savings can be made using the fuel economy engine oils but to maximise savings, it is advised to use fuel economy transmission/backend oil in conjunction.

TotalEnergies’ top-quality lubricants can help save up to 6% on your fuel usage – that’s a saving of over €50/day for a contractor (based on usage of 900L of fuel/day by a contractor making baled silage according to Farm Contractors Ireland and fuel costs at €0.95 /L).

Total Energies says that this can save 600L of fuel and 1.6t of carbon dioxide/machine/annum.

You can use our Fuel Economy Calculator to calculate your potential savings today by clicking here.

Finol Oils has been distributing high quality, approved, internationally branded lubricants for over 40 years.

The experience gained by us over this time in the technical aspects of lubricants and the knowledge we have learned from our international partners, i.e. TotalEnergies and Petro-Canada, means we can offer you impeccable service in helping you choose the right lubricant for your farm machinery and ensuring you can start to benefit from these great cost-savings discussed.

Finol offers the full range of TotalEnergies’ Agriculture Lubricants, Petro-Canada Lubricants and also our own Finol AgriworX range filled with high-quality products, supplied by international-branded partners.

To find out more about the full range of dedicated agriculture lubricants, contact our technical team directly at: 01 4555484 or click here.