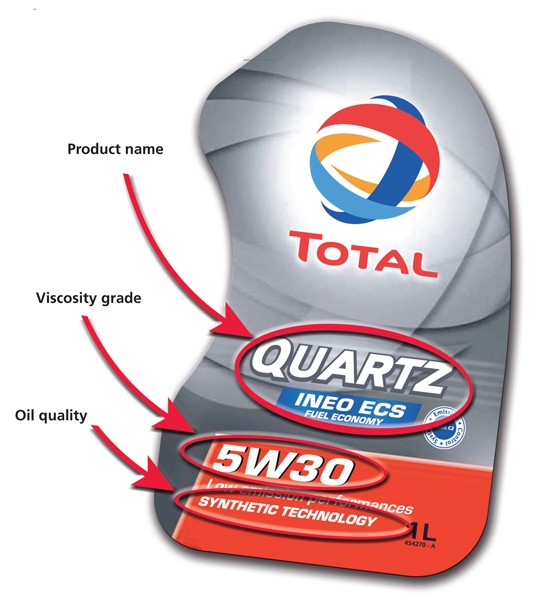

After reading our last blog on what your engine oil does and the importance of choosing the right oil, how do you choose the right oil from looking at it on the shelf? The quality of a lubricant is defined by a number of parameters which can normally be found on the label. This information will enable you to view the properties and performance levels of the lubricant.

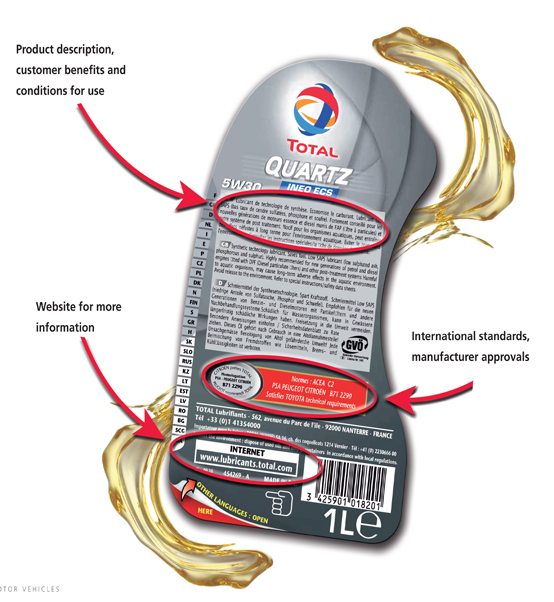

To help you understand how to read the label, we have taken an image of a TOTAL Quartz INEO ECS label and highlighted the main terms & information that is present to help you choose the best oil for your requirements.

Brand & Product Name – This is pretty obvious and any of the big brands will be easily recognisable from their name and logo. The product name will help you in the future as once you find the right product you just have to look for the product name any more.

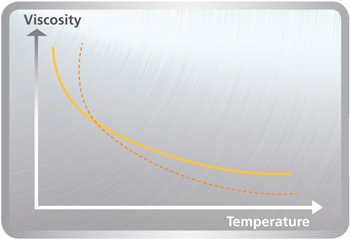

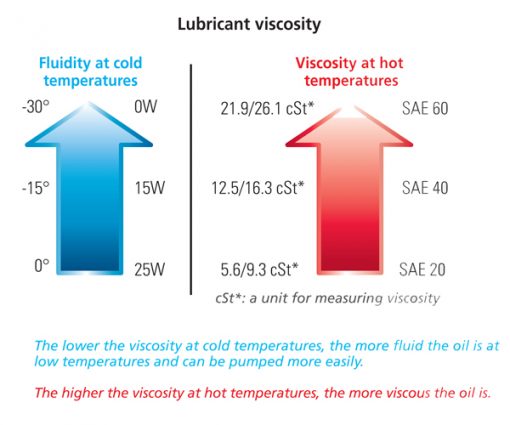

Oil Viscosity – Lubricants behave in different ways at high and low temperatures. Oil can be characterised by its viscosity, flow resistance or by measuring the thickness of the oil film. Viscosity varies according to temperature in the following manner:

The higher the temperature, the more fluid the oil and the lower its viscosity.

This means that if the engine is to perform at its best, the oil must be able to retain its viscosity whatever the heat conditions: it must stay fluid at cold temperatures (to allow the engine to start) and it must be viscous at hot temperatures (to stop the various moving parts coming into contact with each other).

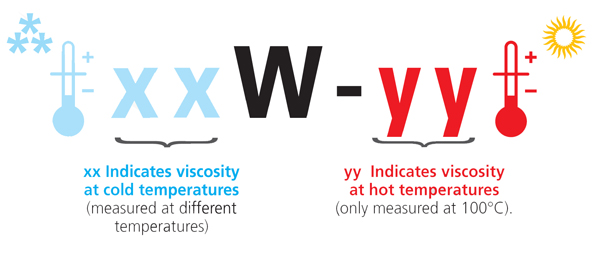

Viscosity Grades – The SAE (Society of Automotive Engineers) has created a classification for lubricant grades in order to characterise viscosity at high and low temperatures. The grades are made up of two numbers, between which is the letter W (for winter grade), as follows:

Oil Quality – There are three main types of oils, depending on which base oil is used in the manufacturing of your lubricant.

- Mineral Oils – these are base oils made from petroleum-based products in their basic formulation.

- Synthetic Oils – these base oils consist of chemical compounds and are preferred to mineral oils which are refined from petroleum. Synthetic oils have superior qualities to the mineral oils.

- Semi-synthetic oils – these are oils made up of blends of mineral & synthetic oil

Product Description, benefits & applications – This area points out the description of the products, the benefits you will see from using it and the different applications for the product.

International Standards & Manufacturer Approvals – The international standards are levels which the performance of the lubricants must meet; they are set by authorities such as API, ACEA, JASO & ILSAC. These standards are set to ensure lubricants have high technical performances. In addition to see these standards on the label you will also see some OEMs (Original Equipment Manufacturers) approvals. These OEM approvals are where the particular manufacturers have set their own standards which are usually more stringent than international standards. The OEMs will all so recommend the use of specific motor oil; this can be seen in your vehicles maintenance guide.

Other Features which may appear on labels

Fuel Economy Lubricants – These lubricants are based on a special formula that helps save fuel compared with conventional oils offering the same level of performance. This characteristic applies essentially to engine oil, but it can also relate to transmission oils for gearboxes, axles, etc

Low SAPS Lubricants – These lubricants contain low levels of sulphated ash, phosphorus and sulphur. This technology optimizes the operation of the depolluting systems fitted to the most recent engines.