One of the most well-known and important lubricants you can buy is hydraulic oil. Found in industrial machinery, construction vehicles, tractors and many other types of machinery, it plays an integral role in their performance capabilities. Hydraulic oil is very different from other lubricants. Like engine oil, hydraulic oil provides protection to moving parts by reducing friction, but its main role is to transfer power throughout the hydraulic system, and this makes it a very lubricant.

Hydraulic Oil is a non-compressible lubricant which means it cannot be compressed. If we take an excavator used in construction sites, external force is applied to the hydraulic oil from a piston (usually found within a cylinder). As the hydraulic oil is non-compressible, the oil is then pushed through the hydraulic system, transferring power and producing force in another system, in this case, allowing the excavator arm to lift or lower.

As demands on the hydraulic system change, they are faced with many forces that mean it is crucial that you pick the right hydraulic oil for the function. Whether it is greater temperatures due to increased speed or extreme pressure due to higher performance, there are several characteristics you need to look at before making that purchase.

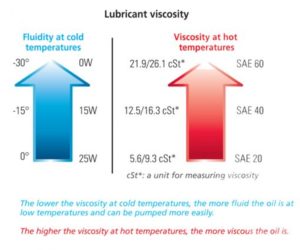

Viscosity is a fluid’s resistance to flow and is the most important property of hydraulic oil. It is a fine Oil Viscosity balancing act between high and low viscosity. A high viscosity hydraulic oil that is too “thick” or viscous cause can several issues for machinery including, slower performance and mechanical efficiency, increased consumption as it takes more energy to perform tasks, high-pressure and pump cavitation.

On the other hand, low viscosity hydraulic oils are very well suited for low drag operations. But they can increase wear, reduces efficiency to compress and can cause leakage as the viscosity is too low or the oil is too “thin” for certain systems. This means identifying the performance parameters of your machinery is vital.

Hydraulic Oils operate in severe conditions constantly with high temperature and pressure the main factor. Over time, these factors can cause the oil to oxidise, forming several contaminants such as varnish, sludge and acid that can cause extensive damage to parts. It is very important to know what additives your hydraulic oil contains. Additives help the overall performance of an oil and in the case of oxidation, should contain an additive that helps provide good thermal stability and inhibits oxidation.

Hydraulic Oils may need to operate in low temperatures high temperatures or even both depending on the machinery and their application. This can cause problems when it comes to choosing the viscosity, while also ensuring the right additives and base oil are being used. High Viscosity Index (HVI) hydraulic oils are specifically designed to hold their thickness at higher temperatures. The wider the temperature range, the higher the viscosity index number will be. Understanding the temperature range that your machinery is operating at will help highlight whether you need a standard or high viscosity hydraulic oil.

During use, a hydraulic oil may look cloudy. This happens when it has been exposed to water well above its saturation level or the amount of water that can dissolve into the hydraulic oil. Water in hydraulic oil has several negative impacts. It can react with additives to corrode parts or deplete the additive altogether. It can increase wear and tear and even clog the filters. Demulsifiers are additives that separate the water from the oil, allowing filters to pick up the water easily, leaving the oil and additives behind to perform.

If you see hydraulic oil foaming, it means that air bubbles have built near its surface. In some cases, the foam may leak out but since foam is a good insulator, it makes it hard to control the temperature of the oil. Foaming is also a sign that the oil is degrading and may lead to increased oxidation and the reduction of lubricant performance as a whole. Anti-foaming additives eliminate foam forming by reducing the surface tension of the air bubble walls causing them to collapse. Ensuring you are using the right viscosity is also important here as hydraulic oil that is too viscous slows down the speed air bubbles navigate through the oil and collapse.

Zinc has been a key component of anti-wear additives. The zinc is used up in a chemical reaction and depleted as they perform their role. But their presence is not always positive. If the zinc levels are too high, they can cause corrosion in some metals. They also impact the environment negatively. It is very important that you identify what type of metal you are using and the zinc content of your hydraulic oil before use.

When exposed to moisture and oxygen, the internal parts of a machine will begin to corrode and oxidise. This can happen if the hydraulic oil is carrying too much water, with it then attacking the metals. To protect against this, additives that provide stability in the presence of water should be considered.

Depending on the base oil that has been used, a hydraulic oil could be clear to a golden honey colour. In some instances, hydraulic oil may also be dyed. With car engine oils the assumption is that once it has changed colour it needs to be changed as it is a clear sign of degradation. Once it enters the hydraulic system, the oil is placed under severe conditions. The hydraulic oil is placed under extreme pressure and thermal stress causing the oil to darken and oxidise. Although oxidisation is a good reason to presume that the hydraulic oil has broken down, colour is not a good indication of the level of oxidation as the colour change may be caused by antioxidant additives. There may also be specific “hot spots” in the system which excessively heats the oil. This may be a sign that repairs are needed.

But a darker colour hydraulic oil is a good indicator that oil analysis is required. Oil analysis will perform various tests to check oxidation, viscosity levels, additives quantity and general degradation. If in any doubt, it is always a good idea to change the oil, so you have complete confidence in both the performance of the oil and machine.

Identifying the right hydraulic oil for your application is no easy feat. Understanding its usage and the many factors it will face in its lifetime will make that decision easier and ensure that your machinery operates at an optimum level. Finol Oils provide a broad range of hydraulic oils to ensure that no matter your needs, we will have the hydraulic oil to support your operation. This range includes the market-leading Azolla and Equivis grades.

Azolla is a range of very high-performance anti-wear hydraulic oils designed for use in a wide array of hydraulic systems that operate under extremely difficult conditions. Providing protection against wear and ensuring maximum system life, Azolla ZS can help reduce maintenance and operating costs while keeping your machinery operating at an optimal level.

Equivis is a high viscosity hydraulic oil specifically designed for hydraulic systems operating in high pressure and extreme temperature environments. Their very high viscosity index, shear stability and anti-wear properties ensure it is suitable for all hydraulic systems including those in construction, agricultural, marine and industrial applications.

To find out more about these high- performance lubricants, talk to our dedicated technical team today at 01-582 7112 or go to www.finol.ie/contact-us.

Hydraulic Oils with Finol

Finol is a leading distributor of Finol, Total, Elf Oils and Lubricants for the Automotive Industry in Ireland. Our extensive range covers of hydraulic oils and lubricants cover a wide array of industries including: Automotive, Agricultural, Fleet, Construction and Industrial.

Contact Us

To get a Free Quote or Request a Call Back on any of our automotive products, don’t hesitate to contact our experienced staff today!